Statement of the jury

“They are always breaking new creative ground" – this best describes the culture of FPT POWERTRAIN TECHNOLOGIES. The management team impressed with its broad positioning in innovation topics, which are primarily developed in their in-house method workshop.

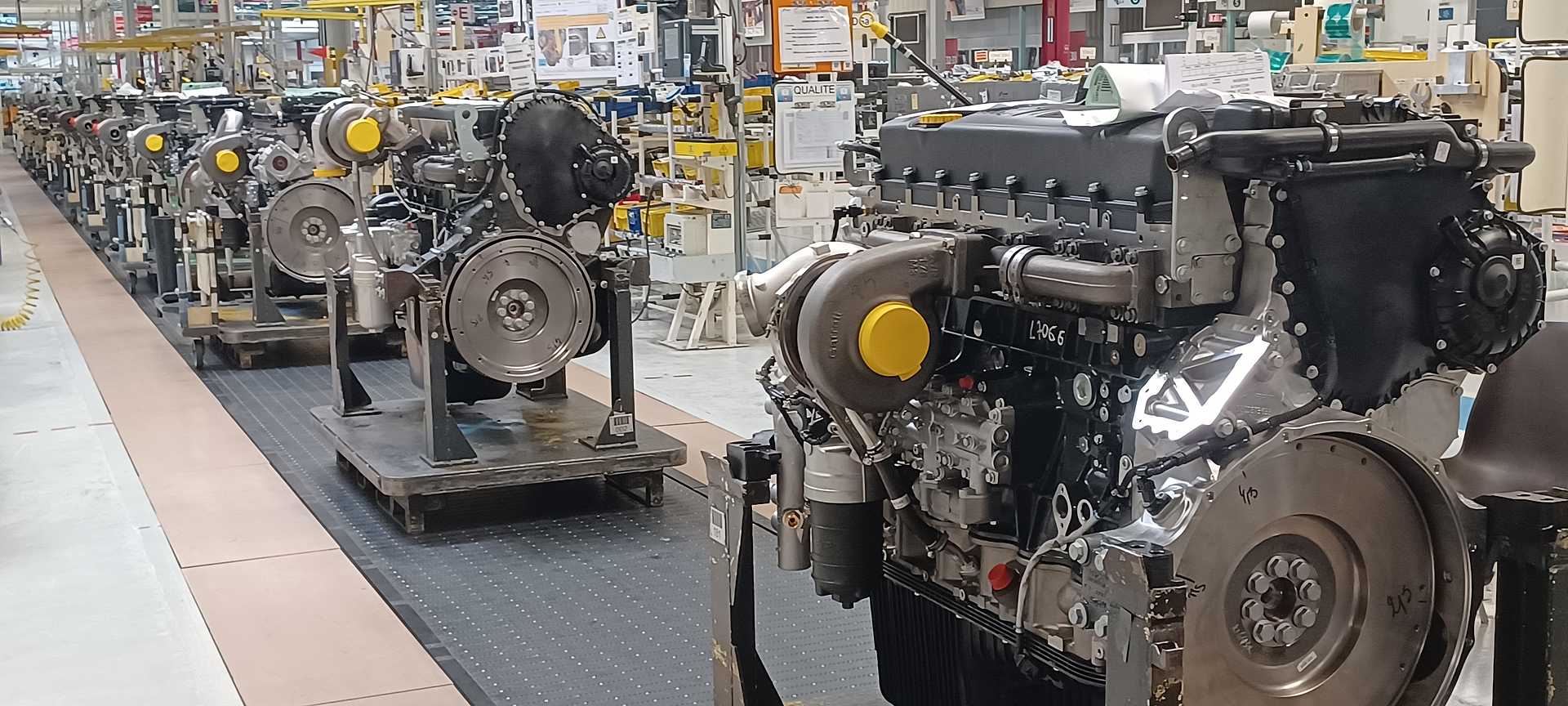

In addition, the management has a strong focus on lean management with a long-term roadmap and many lean experts. The methodological strength - the plant was awarded the World Class Manufacturing Gold Award in 2021 - and the consistency in implementation is particularly evident in the visual management, the optimized material flow, and the continuous standardization of processes.

The implementation of Industry 4.0 in combination with LCA (Low-Cost Automation) approaches is absolutely best-in-class for this size of company, considering that the initiatives are mainly developed and industrialized locally at the Karakuri Academy. This initiative essentially thrives on the involvement of the employees, who are encouraged by a two-day training course to make suggestions for improving their own workplace. The results are then implemented with the Karakuri trainers to solve actual problems (e.g., ergonomics, unbalancing, ...). After the test phase, the resulting solutions are being rolled out to other areas and possibly other plants.

At the plant, one pays attention to building up in-house expertise in complex topics (data science, automation...). Of particular note in this context is the cooperation with the local universities, including state funding for intensive research work on both Industry 4.0 basics (complex) and practical applications (directly usable). This cooperation pursues ambitious goals and is very well managed by the plant management, thus creating highly qualified employee profiles.

With its ambitious roadmap, the management is pursuing a clear strategy of continuous improvement and digitalization. Emphasis is placed on achievable targets with use cases that show a good return on investment (ROI). This applies both to data-driven projects, such as the standardization of TPM via tablet solutions that suggest the necessary spare parts as well as possible solutions to problems, as well as to clever solutions in 3D scanning & modelling.

The evaluation team was also impressed by the intelligent and cost-efficient use of AGVs (Automated Guided Vehicles) in pick-to-light supermarkets. In addition to the classic connection of the pick zone in locations of consumptions, AGVs can also support picking as such using the follow-me method.

What made the jury decide to award the FPT POWERTRAIN TECHNOLOGIES plant?

- Significant improvement in the proportion of processes within the golden zone in assembly using Karakuri methods.

- The great participation of employees in the development of the LCA solutions.

- The consistent elimination of waste through adherence to Lean principles.

- The increase in efficiency achieved would not have been possible without breaking new ground.

- The coexistence of Industry 4.0 solutions, LCA solutions as well as the classic Lean principles.

- The clear vision of industry 4.0 and the feasible implementation steps in a brownfield environment with an older machine park.

Finally, it is important to emphasize the spirit of the leadership teams, which is transmitted to the team and workers. Without this spirit, the successes of the past would not have been possible This is just one of the many reasons why the evaluation team is convinced that the Bourbon-Lancy plant is well-equipped for the future. We look forward to many additional best practice ideas from this plant!

Congress organisation

phone +49 89 44 388 99 22

lean.award(at)agamus.com